State of the art:

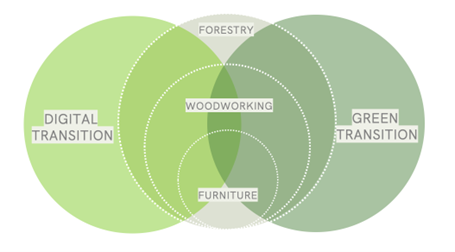

TWIN TRANSITION IN THE WOOD-FURNITURE VALUE CHAIN

State-of-the-art on Environmental Certifications Practices and Industry 4.0 in the Wood and Furniture Sector

Over the recent years, public opinion awareness on the issues of sustainable forest management in light of climate change has increased. Forests are indeed an important factor in mitigating climate change. They provide a wide range of ecosystem services, such as carbon sequestration, protection of soil from erosion and, beyond creating economic value, offer opportunities for recreation.

Currently however, 30% of the wood used in the EU comes from countries where illegal logging and partial deforestation is usual. In this context, certified forests, wood and products, combined with eco-design and framed within a circular economy can be considered as the most appropriate approach to deal with this issue.

Moreover, in today’s market, environmentally friendly products have a clear competitive advantage due to the rapid increase of consumers concerned about the environmental impact of their activities and goods they purchase. This in turn, results in a market trend to buy certified products instead of non-certified products. For instance, at the end of 2019, approximately 97% of the wood used by IKEA came from sustainable sources.

In this context, different certifications have been created to manage forest-based products, like the Forest Stewardship Council (FSC) and EU Timber Regulation (EUTR). Such schemes are normally integrated into environmental management systems, based on standards like ISO 14001 or EMAS, that, along with other tools and schemes like life cycle assessment and Ecolabels, help companies in the processes and procedures related to the use of certified wood in construction or furniture manufacturing.

Meanwhile, the rise of Industry 4.0 (I4.0) leads to the discussion of how forestry and the wood sector in general can benefit from this development. The economic potential of Industry 4.0 in forestry could lead to an increased 15% value. Smart wood supply chains are slowly reshaping the industry with several new applications in use or in research and development. This revolution can lead to significant changes and new value creation.

The combined green and digital transition thus offer a promising avenue for manufacturing enterprises of the sector.

The report Twin Transition In The Wood-Furniture Value Chain provides an overview on the current environmental and digital trends and practices affecting the wood value chain in its entirety. Taking a value chain perspective, the report outlines regulatory trends, new digital and technological development, as well as emerging practices that are to affect the sector as a whole.

KEY LEARNINGS

- Industry 4.0 is revolutionising the way companies manufacture, improve and distribute their products. Manufacturers are integrating new technologies, including Internet of Things (IoT), cloud computing and analytics, and AI and machine learning into their production facilities and throughout their operations.

- This fourth industrial revolution presents great opportunities for the forest-wood-furniture value chain: Sensor’s development, high computing capacity, industrial internet (Internet of Things, IoT) and learning algorithms can allow a much better handling of uncertainty and material variability.

- As European SMEs of the wood and furniture industry must adapt to evolving legislations and standards at the international, European and national levels, the use of new, more sustainable technologies can allow companies to reduce their environmental impact according to new standards without increasing costs.

- More than any other, the wood and furniture industry faces issues related to the management of natural resources. Dozens of certifications, labels and management systems are being offered to the industry to highlight and improve their environmental performance.

- By implementing intelligent systems and new production processes, European SMEs can optimize usage of raw materials, improve their waste management and contribute to the development of a circular economy. This digital and green transition however will not be implemented if the staff among the value chain does not acquire the right knowledge and skills on the value offered by industry 4.0 in developing more sustainable management practices.

The state of the art will ultimately be used as a basis to develop a dedicated training curriculum – the key objective of the INTRuST project – that can support stakeholders of the wood value chain in integrating digital and green practices into their operations.